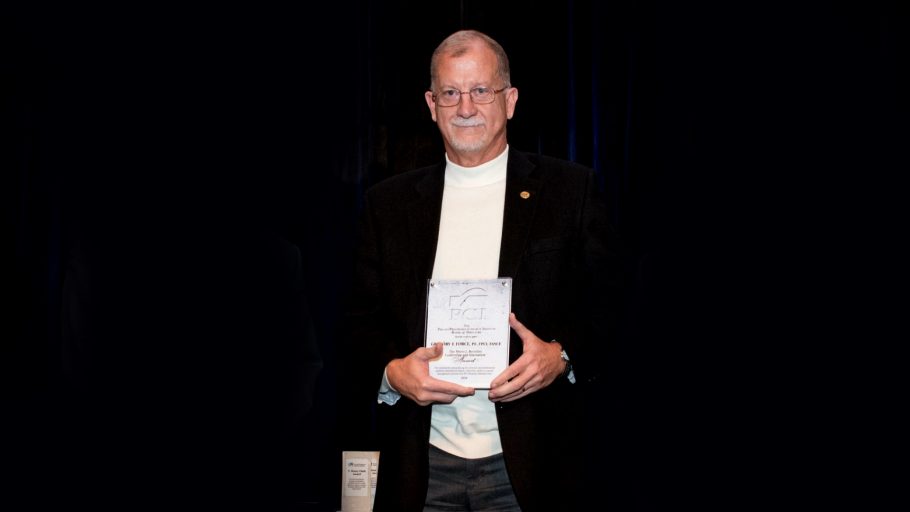

Greg’s decorated career at Tindall began in 1988. Named a Titan of the Industry by PCI in 2014, he became CEO of Tindall in 2018.

The same innovative spirit that drives the advancement of digital technologies inspires Tindall to develop new, more efficient precast, prestressed concrete solutions to house their data.

The rapid advancement of technology since the 1960s is simply staggering. 60 years ago, the electric calculator had just been invented, color TV was becoming popularized for the first time, and the Internet was still decades away from deployment. So, how did we arrive here—where supercomputers live in our pockets, where access to the world’s collective knowledge is always within arm’s reach, and where self-driving cars are on the precipice of normalcy?

Simple: People pushed the boundaries of what’s possible by committing to innovation—dedicating their lives to developing solutions to never-before-seen challenges. It’s the same way that Tindall Corporation evolved from a simple concrete pipe company to become one of the largest, most experienced producers of precast, prestressed concrete in North America and an industry leader in total precast data center construction.

When William Lowndes III purchased Tindall in 1963, the small plant operated out of a shed with just six employees. Even then, Tindall’s founder had a vision for what the company would become. Innovation drove him, and he approached each new challenge by asking, “How can we solve this, and can we solve it more efficiently, more cost-effectively, and with better performance?” These questions—the types asked by visionaries across every industry—drove Tindall to adopt their founder’s innovative spirit and commitment to pushing precast concrete further than ever before.

Within three years, Tindall built a reputation for precast utility products and broke into the world of prestressed concrete—creating optimized methods and discovering opportunities for improved efficiencies along the way. By the 1970s, Lowndes began looking to the north and west with the idea of expansion. As the opportunities arose, he took them, establishing Tindall’s presence solidly in Atlanta, Georgia and soon thereafter in Petersburg, Virginia. However, Lowndes knew more facilities alone wouldn’t carry Tindall to new heights, so with innovation fueling the business’s momentum, Tindall began developing a competitive advantage that few in the industry could match.

While other precasters remained content producing standardized components, Tindall sought the capability to develop custom precast solutions—something that required the technical know-how and expertise of an in-house engineering team. By 1983, Lowndes was at Clemson University interviewing engineering graduates and developing the foundation for his team, and over the next few years, Tindall’s capabilities, capacity, and creativity soared.

By the late 80s, Tindall had facilities capable of serving the Southeastern and Mid-Atlantic portions of the country. Now armed with significant engineering expertise and driven to create new, better, more efficient solutions, Tindall leveraged its capacity and experience to take on challenges that no other precast company had even thought to tackle.

The first were paper mills, which traditionally relied on heavy steel or cast-in-place concrete structures to withstand the heavy vibrations caused by their machinery. Tindall found several more-efficient precast solutions for these structures—the first of their kind. Simultaneously, the team developed strategies for educating the industry on the value and capabilities of precast, prestressed concrete—a challenge nearly every precast provider at the time hoped to overcome.

ABOUT THE AUTHOR

Greg was named CEO of Tindall Corporation in 2018 after serving as President and COO for 14 years. An active member of the Precast, Prestressed Concrete Institute (PCI) for over three decades, he was named a Titan of the Industry in 2014. Today, Greg oversees the growth and financial strength of Tindall’s five manufacturing facilities and remains dedicated to innovation in numerous markets, including data centers, industrial applications, education, and more.